Production

The Comey raised access floor factory has four production lines. A unit close by provides a fifth line of products. Our strategic location in the Yonne region, 140km south of Paris at the crossroads of the main French motorways means we can optimise lead times and transport costs. The aluminium ranges and Isofloor structures are produced in Sweden and in Korea.

15 specialised workers in a 5,000m2 workshop are assigned to the production of Comey floors. The factory produces between 250,000 and 350,000m2 of pressed wood panels, calcium sulphate panels, steel panels and steel structures.

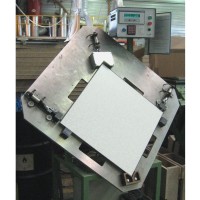

Thanks to the know-how and experience gained from the company's mechanical origins, all the machines and equipment have been specially developed by our own technicians at Comey for the production of our raised access floors.

The raised access floors produced in our factories undergo strict controls at each stage of production.

- Raw materials management: the workshop receives and checks the wood, steel, glues, coverings, etc. which will be used to manufacture the panels.

- Assembly: the coverings are glued onto the core of the panels

- Machining: the panel is then machined to the required dimensions

- Finishes: gluing on of the trough or underside

- Packaging

- Shipping

A rigorous procedure ensures perfect traceability.

Conditions Générales de Ventes

Conditions Générales de Ventes